In modern machining, hardly any other factor has as much influence on productivity, quality, and tool costs as targeted and stable cooling. The demands placed on machine tools are constantly increasing: higher cutting speeds, more challenging materials such as Inconel or titanium, tighter tolerances, and increasingly complex machining operations. At the same time, processes are expected to run stably, with repeatable accuracy, and economically.

Nevertheless, cooling remains an often underestimated issue in many manufacturing companies—until problems arise: unexpected tool wear, dimensional deviations, poor surfaces, or uncontrolled chip flow. These are all symptoms of insufficient or incorrectly aligned coolant supply.

This article shows why proper cooling is crucial, which physical processes play a role, and how stable, precisely adjustable coolant hoses (e.g., stainless steel joint systems) contribute significantly to process optimization.

1. Why cooling is essential in machining

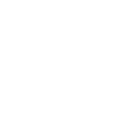

During machining, temperatures of several hundred degrees Celsius are generated at the cutting edge of the tool. Depending on the material—especially in the case of difficult-to-machine materials—temperatures can even exceed 1,000 °C. .

This heat affects the entire process:

- The tool loses hardness and wears out faster.

- The surface deteriorates

- Chips can lubricate or stick together

- Dimensional stability suffers due to thermal expansion

- Process instability is increasing

The main functions of the coolant are therefore:

- Cooling Reduction of thermal stress on the tool and workpiece.

- Lubrication Reduction of friction between chip and tool.

- Avoid building up cuts or surface damage.

- Remove chips Keep the cutting area clear to prevent jamming,

- Cleaning Transport of particles from the processing zone.

However, these effects only occur if the coolant is applied precisely, constantly, and with sufficient pressure to the exact location where it is needed: directly at the cutting edge.

2. The physical challenges: Why cooling often fails

The biggest mistakes in cooling rarely occur at the unit or the machine, but rather at the last section of the coolant system: the nozzle or coolant hose.

Typical causes of insufficient cooling:

- Chip removal does not work reliably

- The nozzle is misaligned

- The beam does not hit the cutting edge, but rather the workpiece or the chips.

- The coolant pressure is too low or too high.

- The hose moves during processing

- The temperature is rising uncontrollably.

- The coolant flow is deflected by chips.

- Straight flexible plastic hoses often become misaligned due to:

- machine vibrations

- chip impact

- pressure changes

- material fatigue

The result: the beam moves away from the cutting edge—and the problems begin.

3. How correct coolant alignment affects tool life

Tools wear out mainly due to:

- abrasion

- adhesion

- oxidation

- Thermal shock

All these mechanisms are directly related to the temperature in the cutting zone.

Better cooling = longer service life

When coolant hits the contact area between the chip and the tool shank, the following happens:

- Thermal cracks are reduced

- the cutting edge remains harder

- the chip flow becomes more stable

- friction decreases

- the wear mechanism slows down

- Dimensional stability lasts longer

Studies show:

Even a 5–10% improvement in coolant alignment can increase tool life by 30–50%—without changing any process parameters.

But to do that, the beam must be stable and hit the target with pinpoint accuracy.

4. Jet quality and pressure: Why the type of nozzle is crucial

Coolant nozzles are not all the same. They differ in:

- Jet shape (focused, fanned out, laminar, turbulent)

- outlet cross-section

- volume flow

- pressure resistance

- positionability

Choosing the right nozzle affects:

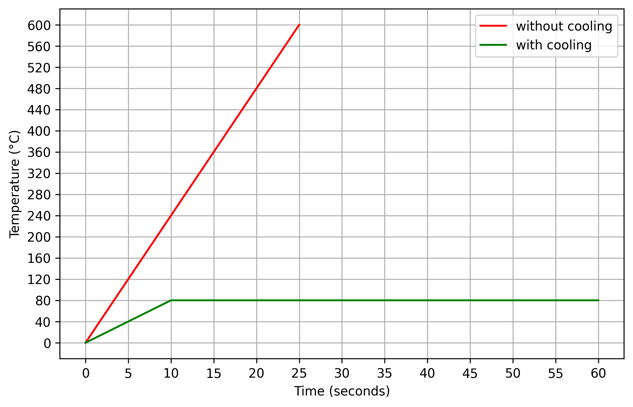

- how deep the coolant penetrates to the chip root

- whether chips are broken or washed away

- whether the beam reaches the contact point or is deflected

For steel processing:

A focused beam is usually the most efficient.

For grinding operations:

A laminar jet prevents grinding marks and heat input.

For high-pressure applications (>70 bar):

The stability of the entire system is crucial.

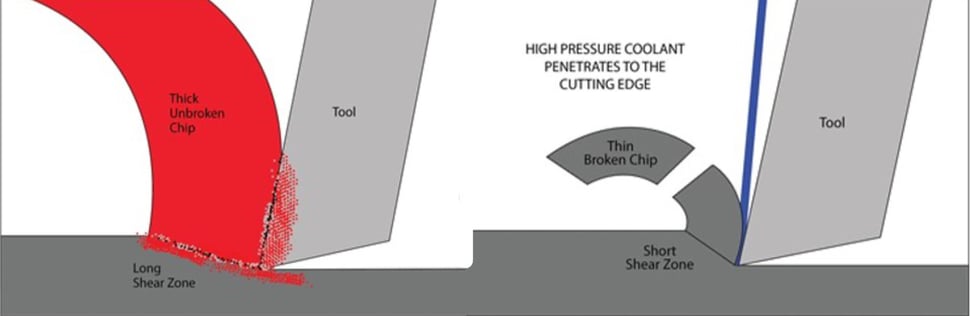

This is precisely where there is a major difference between plastic and stainless steel coolant hoses.

5. Why stable hoses are crucial—and why plastic systems often reach their limits

A coolant system can only function optimally if the position of the nozzle remains constant. In practice, however, the cooling system often becomes misaligned without anyone noticing.

Common problems with plastic hoses:

- lose position due to vibrations

- bend or sag

- are hit by chips and twisted

- deform due to temperature

- relieve at high pressure

This causes the beam to suddenly:

- no longer hits the cutting edge

- splashes against the workpiece

- is several millimeters off

- hits the chips instead of the tool

A single incorrectly directed beam can cause tool breakage, dimensional deviations, or even surface damage.

Stainless steel coolant hoses solve this problem.

Thanks to their mechanical strength, vibration stability, and temperature resistance, they remain stable even under:

- >100 bar pressure

- long processing cycles

- continuous vibrations

- high temperature

- chip impact

- absolutely position-accurate

Once set, the beam stays exactly where it belongs—until the tool is changed.

6. Cooling as an economic factor: Why precision cooling saves money

Many manufacturing companies underestimate the economic impact of optimal cooling. Yet the effect is easily quantifiable.

Consistent cooling saves costs by:

- less tool wear

- longer service life

- less reworking

- reduced reject rate

- more stable manufacturing processes

- less machine downtime

- higher cutting speeds

Small optimizations can have a big impact, especially in series production.

Example:

- A tool costs €30.

- One machine produces 80 parts per shift.

- Improved cooling increases service life by 40%.

➡ This saves four-figure sums per machine every year, simply by improving the alignment of the coolant jet.

Stainless steel coolant hoses therefore often pay for themselves in just a few weeks.

7. Conclusion: Proper cooling is not a minor detail—it is a performance-determining process factor.

If you really want to optimize machining processes, you need to consider not only tools, cutting data, and machine parameters, but above all: the

- How efficiently does the coolant reach the cutting edge?

- Does the beam remain stable throughout the entire process?

- Can the nozzle or hose system withstand the conditions?

Precise, stable, and temperature-resistant coolant delivery is not just a "nice to have," but a fundamental component of modern manufacturing.

Stainless steel articulated coolant hoses offer decisive advantages here:

- high pressure and temperature resistance

- absolute positional accuracy

- durable and robust construction

- precise alignment of the nozzles

- less maintenance

- lower tooling costs