COLD AIR NOZZLE (HL6910.15)

WITH VA JOINT HOSE

By using cooled air, the temperature in the cutting area is reduced, allowing higher cutting speeds and tool life to be achieved. Modern This type of cooling allows modern coatings to show all their advantages, as damage to the cutting edge due to thermal shock is avoided.

In addition, the very light chips produced during copy milling are also removed from deep recesses or cavities with the aid of the cold air nozzle.

The principle of the cold air nozzle is based on the action of vortex tubes.

Ordinary compressed air is divided into a cold and a hot air flow.

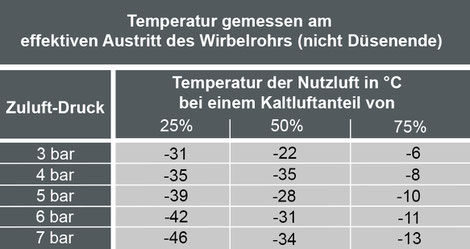

Without additional energy supply through electricity or moving parts, the cold air nozzle can achieve a cooling capacity of up to 733 W or temperatures of approx. -40 °C

and only requires operating compressed air of approx. 6 bar. A water separator or a maintenance unit should be installed upstream.

A control valve in the hot air outlet regulates the temperatures and flows.

The drawing below illustrates the operation of a cold air nozzle. Compressed air enters a tangentially drilled, stationary generator, which forces the air along the long inner wall of the pipe in a circular motion towards the hot air control valve. This forces the air along the long inner wall of the pipe in a circular motion towards the hot air control valve, generating sonic velocity. A portion of the air escapes through the needle valve at the hot air outlet. The The air that does not escape is forced back through the centre of the sonic velocity airflow, causing a simple heat exchange. The inner air spiral - with slow movement - transfers heat to the outer, faster spiral. By the time the inner spiral exits through the centre of the stationary generator and out of the cooling air exhaust, it has reached an extremely low temperature. The flow rate of the outer stream (hot air) is always higher than that of the inner stream (cold air) because part of the outer stream is discharged via the hot air valve. is diverted.

ATTENTION: To operate the control valve, the rear silencer must be unscrewed - risk of burns!!!

The vortex tube of the hot air side can reach up to 100 °C - Cool down before touching!