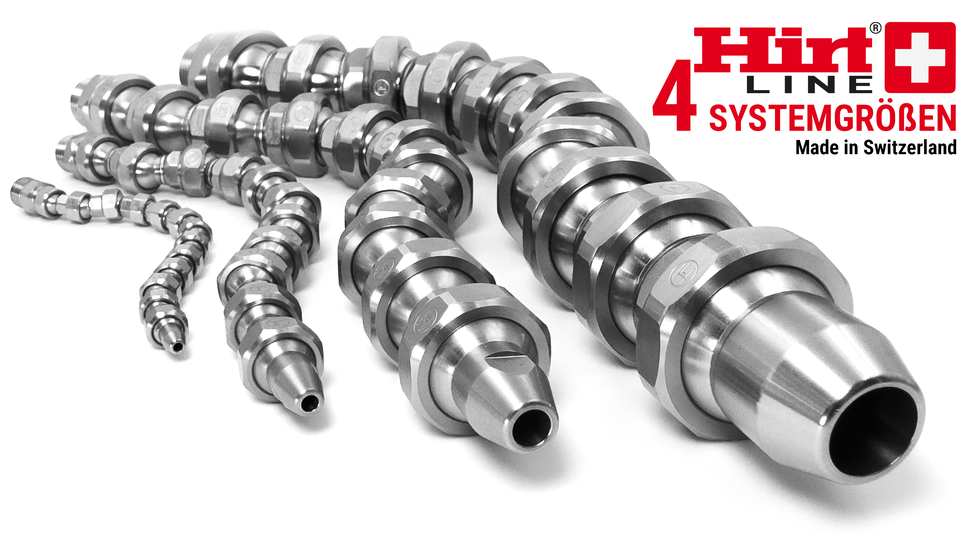

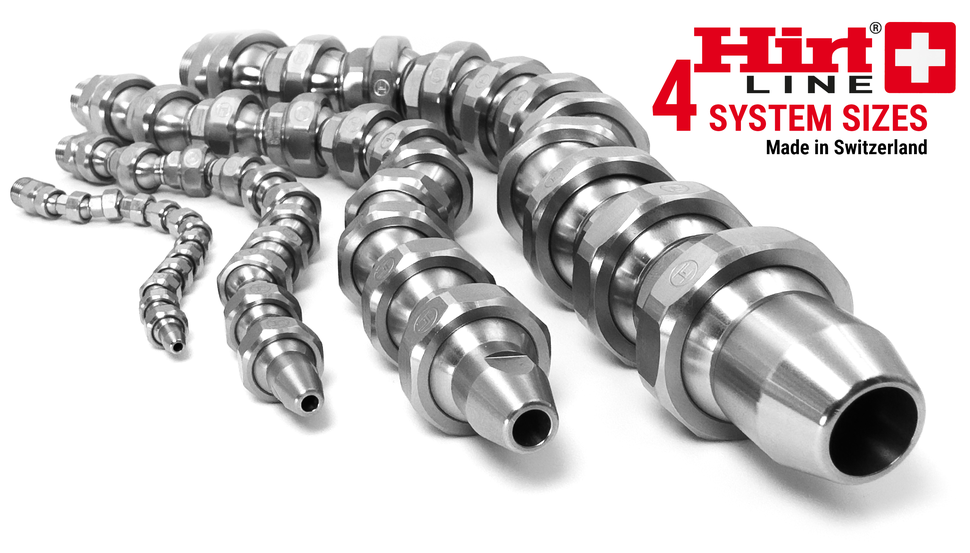

Stainless steel articulated hose Hirt-Line system

#100 bar pressure and vibration stable!

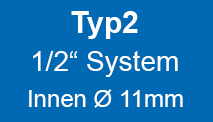

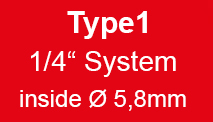

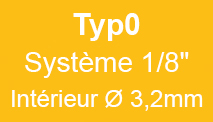

//4 Systemgrössen

#Various coolant nozzles

INDIVIDUAL AND FLEXIBLE

Our articulated hose system redefines flexibility: expandable at will, rust-free and with an exceptionally long service life. The precision-manufactured individual parts withstand heat and chemical chemical substances effortlessly. The system can be easily screwed together, adjusted, extended and shortened by hand. Even under extreme conditions, the coolant nozzles remain remain immovable - neither coolant pressure nor machine vibrations can change the position of the nozzles. With an impressive pressure resistance of over 100 bar, our articulated hose system offers maximum safety and reliability. With the Hirt-Line system, you need less pump power as it makes the flow more efficient. This reduces energy consumption is reduced, which leads to a noticeable reduction in electricity costs. Benefit from optimized operation and save energy and costs at the same time.

INNOVATION MEETS VERSATILITY

PROPERTIES:

- Beam can be adjusted and fixed with pinpoint accuracy (screwable)

- Resistant to high temperatures, new up to 300 °C

- Chip, pressure and vibration resistant

-

Corrosion-resistant material V2A 1.4305 (AISI 303) or V4A

- Wear-resistant and resistant to many chemical substances

- Pressure stable over 100 bar

- 4 system sizes, all compatible with each other

-

Long service life, mechanically tight without sealing rings!

- Can be used directly on the tool (AGW connection)

- Versatile combinable

- Well thought-out and effective assortment

-

Can be used in the food industry and medical technology

- Connecting elements and nozzles for every machine

-

Starter sets available in each system (0-GS, 1-GS, 2-GS, 3-GS)

Interest aroused?

Contact us today to find out more about our solutions andtogether to find the optimum solution for your requirements.

Contact

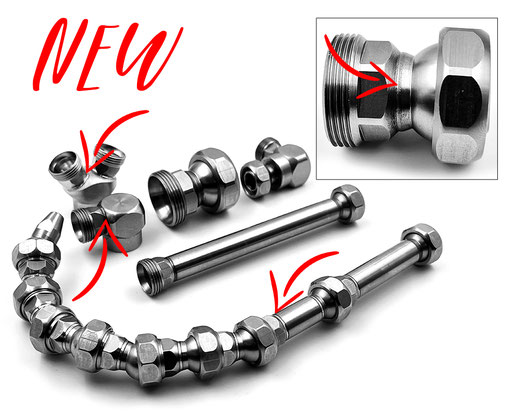

NEW system upgrade

The unique system upgrade takes our Hirt-Line coolant hoses to a new level: stable up to temperatures of 300°C and with an even higher mechanical load capacity.

higher mechanical strength. All relevant system elements have now been welded to ensure an even more robust construction.

Our Hirt-Line coolant hoses are the perfect solution for a wide range of applications. Not only do they fit seamlessly on lathes, milling machines, grinding machines, sawing machines and They are also ideally suited for use with emulsions, cooling and cutting oils and chemical substances. They can also be used for efficient air cooling and in medical medical technology. Rely on Hirt-Line for outstanding quality, performance and versatility - no matter what environment you are working in. Discover the possibilities of our improved coolant hoses and take your manufacturing processes to a new level.

New "Flat jet nozzles for grinding processes".

Efficiently cooled!

The cooling lubricant supply is often neglected because it is wrongly considered unimportant. However, the cooling lubricant supply makes a significant contribution to process process reliability. It is therefore not advisable to rely on narrow pipes or similar constructions, as these cannot guarantee an adequate supply of cooling lubricant. can be guaranteed. In order to deliver the cooling lubricant effectively to the cutting point, it is advisable to use flat jet, round or needle nozzles. Due to the optimized flow of the cooling lubricant, the jet can be precisely directed to the cutting point. It should also be possible to precisely adjust the outlet angle and outlet speed, to optimally adjust all process parameters.

Optimum cooling during grinding is a challenge. In addition to the direct supply of cooling lubricant to the machining zone, cooling lubricant can also be transported via the grinding wheel. cooling lubricant via the grinding wheel, cooling lubricant nozzles can be used for impregnation. These nozzles clean the free pore spaces of the grinding wheel and then fill them with cooling lubricant before the wheel is cooling lubricant before the wheel is re-engaged. The cooling lubricant transported in this way reaches the machining zone precisely and can cool the process reliably.

"Optimum cooling is essential to achieve top-quality sanding results.

In contrast to nozzles with holes, only nozzles with slots fulfill these high

requirements because the coolant jet is "drawn in" between the workpiece and the grinding wheel without

air pockets between the workpiece and grinding wheel. Hirt-Line

offers you a unique selection of precision-manufactured nozzles made of stainless

steel for grinding operations of the highest quality for wheel widths from 18 - 121mm and

jet thicknesses from 0.4 - 2.2mm."

With flat jet and round nozzles from Hirt-Line, a new era is dawning for cooling systems in grinding, turning and milling - more efficient, more sustainable and with shorter set-up times. set-up times. This benefits not only our customers, but also the environment. This is because a large proportion of the electricity and water consumption in the machine process is caused by cooling. In view of rising energy prices and sustainability obligations, it is therefore all the more important that technological development in this area continues. Hirt-Line, with its nozzles and the connected Hirt-Line system in 4 system sizes, Hirt-Line has a real all-rounder. With an ingenious cooling concept based on longevity, which saves both energy and resources to a considerable extent and significantly simplifies operation. Hirt-Line nozzles can reduce water consumption by 30 percent and energy consumption by as much as 40 percent. These are significant savings. But how is this achieved? In a nutshell: Through a sophisticated nozzle design, process-reliable screw connections and a quick coupling for faster set-up times. faster set-up times. Try it out, you won't be disappointed. New in the range: coolant nozzles for grinding wheel widths up to 121 mm.

New "Coolant hose with magnetic base"

Get the perfect solution for your coolant applications! Our innovative and unique coolant hose made from high-quality stainless steel not only offers impressive

durability, but also a strong magnetic base with a pulling force of up to 2x 30 kg.

Whether in the workshop or in industrial use - this hose stays exactly where you need it. Benefit from maximum flexibility and safety for your projects.

projects.

Trust in quality and performance!

Available in 2 set sizes, Type1 or Type2 or magnetic block individually.

✔Compatible with Hirt-Line® 1/4" system (type 1) or 1/2" system (type 2)

Can be used flexibly

✔For the passage of liquids or air

Can be extended or shortened as required

✔Resistant to various chemicals and solvents

✔Material stainless steel V2A 1.4305 (AISI 303)

✔Vibration and pressure resistant

✔Can be combined with other accessories as required

VarioJET VJ14

The first retrofittable and freely programmable

coolant nozzle with automatic data exchange

via tool offset of the machine.

- Increase of the cutting data

- Increasing the service life

- Washing away annoying chips

- Less lubricant required

- Programmable via W-LAN,

(iOS and Android compatible)